Phosphorus Removal

The Rules on Phosphorus in Wastewater Discharge

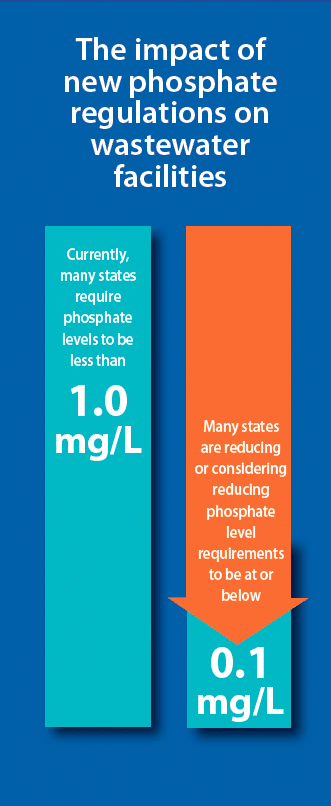

Phosphorus removal is a bigger issue today than ever before. State laws limit the levels of phosphorus that can be discharged from wastewater into the environment. Generally, the enforcement of these laws also happens at the state level. Many U.S. states currently regulate, or will soon regulate, these phosphorus levels. Some states are contemplating switching to new, more stringent standards—in some cases as low as 0.1 mg/L. That’s ten times lower than the current standard.

Why All the Fuss About Phosphorus?

Phosphorus is found in almost every fertilizer that is manufactured commercially. After crops are fertilized, the excess nutrients in the fertilizer, like phosphorous, are washed into our watershed.

While phosphorus is very effective at increasing plant growth in food crops, it has dangerous side-effects for state waterways. The issue is, phosphate also promotes eutrophication—the growth of aquatic plants in bodies of water, which includes harmful algal blooms (cyanobacteria). These cyanoHABs can produce noxious toxins that are harmful to both humans and animals.

Approaches to Phosphorus Removal in Wastewater

As phosphorus issues persist, regulations that limit levels in wastewater will become more strict. For many treatment facilities, understanding how to effectively remove phosphorus from their effluent might be a challenge, but it is surely possible.

Almost all wastewater treatment plants perform at least a secondary treatment, but this typically does not provide enough phosphorus removal. To meet the new requirements, facilities can do one of two things: 1) retrofit their plants to enhance biological treatment processes, or 2) add chemistry to help precipitate out the phosphate. Treatment technologies that are presently available for removing phosphate include:

• Physical: Filtration for particulate phosphorus or membrane technologies

• Chemical: Precipitation or physical-chemical adsorption

• Biological: Assimilation or enhanced biological phosphorus removal (EBPR)

Physical Treatment

One approach that works well to nitrify and denitrify wastewater is to retrofit existing wastewater plants with particulate phosphorus membrane technologies; however, this method may lack the intended benefit of phosphate removal. Furthermore, due to the high capital cost of investment required upfront, it may take years to see a return on investment. Over the long term, however, this process can be a cost-effective solution to reduce phosphate levels.

Chemical Treatment

One tactic that has been used in phosphate management for a long time is chemical precipitation. While this method requires low capital cost, it does come with an ongoing treatment expense. The benefit of using a chemical treatment to lower phosphate levels in wastewater is that it can provide immediate results without the wait for construction (of a physical solution). However, traditional chemical treatments can add significant sludge removal costs; these costs can be especially extreme if the method used is the application of lime during primary treatment (Tchobanoglous et al., 2003). The use of alum after secondary treatment can produce less sludge, but the increase could still be an issue.

Biological Treatment

Biological phosphate removal can effectively lower phosphate levels; however, its performance varies during the year due to several factors like flow, water, air temperature, etc. There is, nevertheless, some concern about the effects that solids management processes and return side streams may have on a biological treatments’ ability to lower phosphate levels. Any process that destroys organic material (such as digestion) has the potential to release particulate organic phosphate, which is present as soluble organic or inorganic phosphate. Any released phosphate will then be returned to the main wastewater treatment process in high concentrations through recycle side streams; because of this, phosphate removal is required a second time. Processes that are not continuous may also cause variable loadings from side streams.

ATS Innova Phosphate Treatment Plan

In most cases, wastewater plants can effectively reduce phosphate levels using a smart chemical approach, for a fraction of the cost of infrastructure upgrades. After working with wastewater facilities across the U.S. for over 30 years, ATS Innova has identified certain variables that should be considered in order to dial-in an optimal chemical solution. These factors include the following water attributes:

- pH

- Alkalinity

- Influent phosphate levels

- Influent ammonia levels

- Influent nitrate levels

- Daily plant effluent volume

When traditional chemicals like alum, ferric, or other products are not doing enough to lower phosphorus levels, many facilities tend to react by simply dosing more. All too often, however, this approach merely results in added cost, more sludge, and increased handling costs—among other problems.

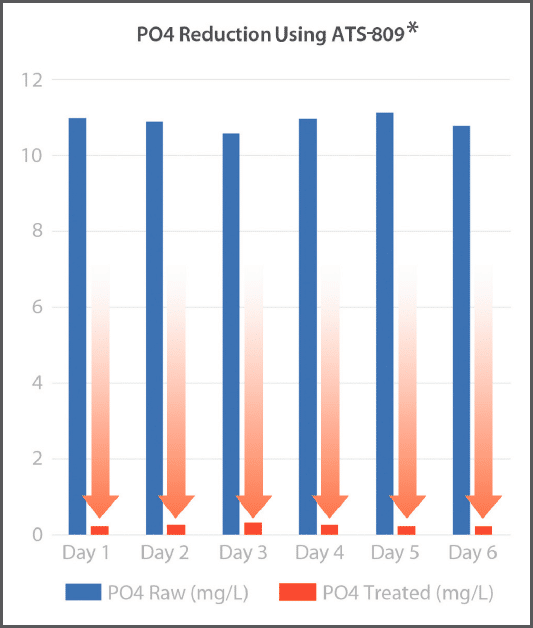

Rather than simply dosing more chemical, ATS Innova helps wastewater plants determine the best chemical strategy for phosphate removal at each unique plant. Our water experts first assess current state water dynamics and then analyze the best location(s) for treatment. Specialty, high-performance chemistry solutions will be recommended based on plant variables. Next, we perform bench-scale testing to validate performance. To ensure everything runs smoothly, the ATS team offers support throughout the startup process, as well as safety training for the implemented solution.

Get ahead of the phosphate regulation curve—Call us today at 855.215.4600 for your free plant analysis and to learn how you can achieve optimal performance with your facility’s unique water dynamics.

UNSURE OF YOUR NEXT STEP?

CALL 855.215.4600